Provides convenience for lightweight vehicle bodies

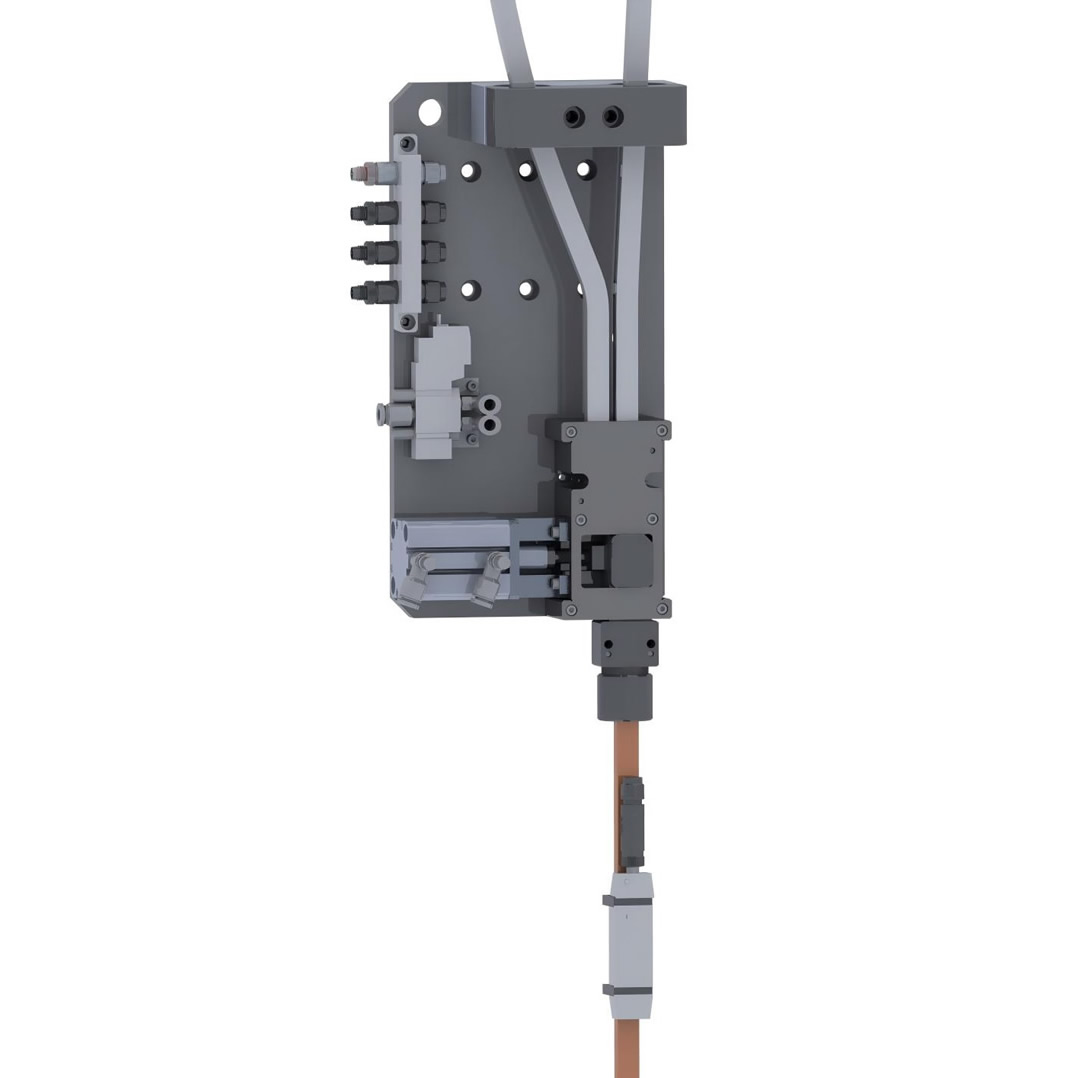

The Direct-Blowing SPR Equipment utilizes pneumatic rivet feeding technology, where compressed air blows rivets directly to the gun head, achieving ultra-efficient continuous riveting.

This makes it suitable for high-volume, high-takt time production, such as in automotive manufacturing and consumer electronics.

• Multi-Gun Sharing & Switching: Supports the use of multiple tools with one controller.

• Expanded Recipe Storage: Capacity to store 500 riveting programs.

• Quality Monitoring & MES Integration: Real-time data tracking with seamless connection to Manufacturing Execution Systems.

• Centralized Group Control: Enables management of multiple systems from a single station.

• Massive Data Storage: 200GB capacity for archiving over 100,000 riveting records.

• High-Capacity Hopper: Stores up to 3,000 rivets to minimize downtime.

• Integrated Rivet Length Detection: Automatically verifies rivet dimensions for quality control.

• Smart Code-Scanning Function: Scans codes to prevent rivet mix-ups, ensuring flawless operation.

• Seamless Multi-Hopper Linking: Offers plug-and-play expandability for uninterrupted production.

• Versatile Rivet Handling: Accommodates multiple rivet specifications without any mechanical adjustments.

• Designed for Direct-Blowing system

• Supports Multi-Module Setup: It can handle a variety of rivets simultaneously for enhanced flexibility.

• Features Simple Installation: The unit can be securely fixed in multiple positions for easy integration.

● Max Force up to 80KN

● Speed up to 280mm/s

● Open throat up to 250mm

● Cycle time ≤ 3.5s