FDS, also known as the Flow Drill Screw , is a high-performance fastening solution for modern manufacturing. It utilizes a high-speed rotating screw to generate frictional heat, enabling strong joints from one side without the need for pre-drilled holes.

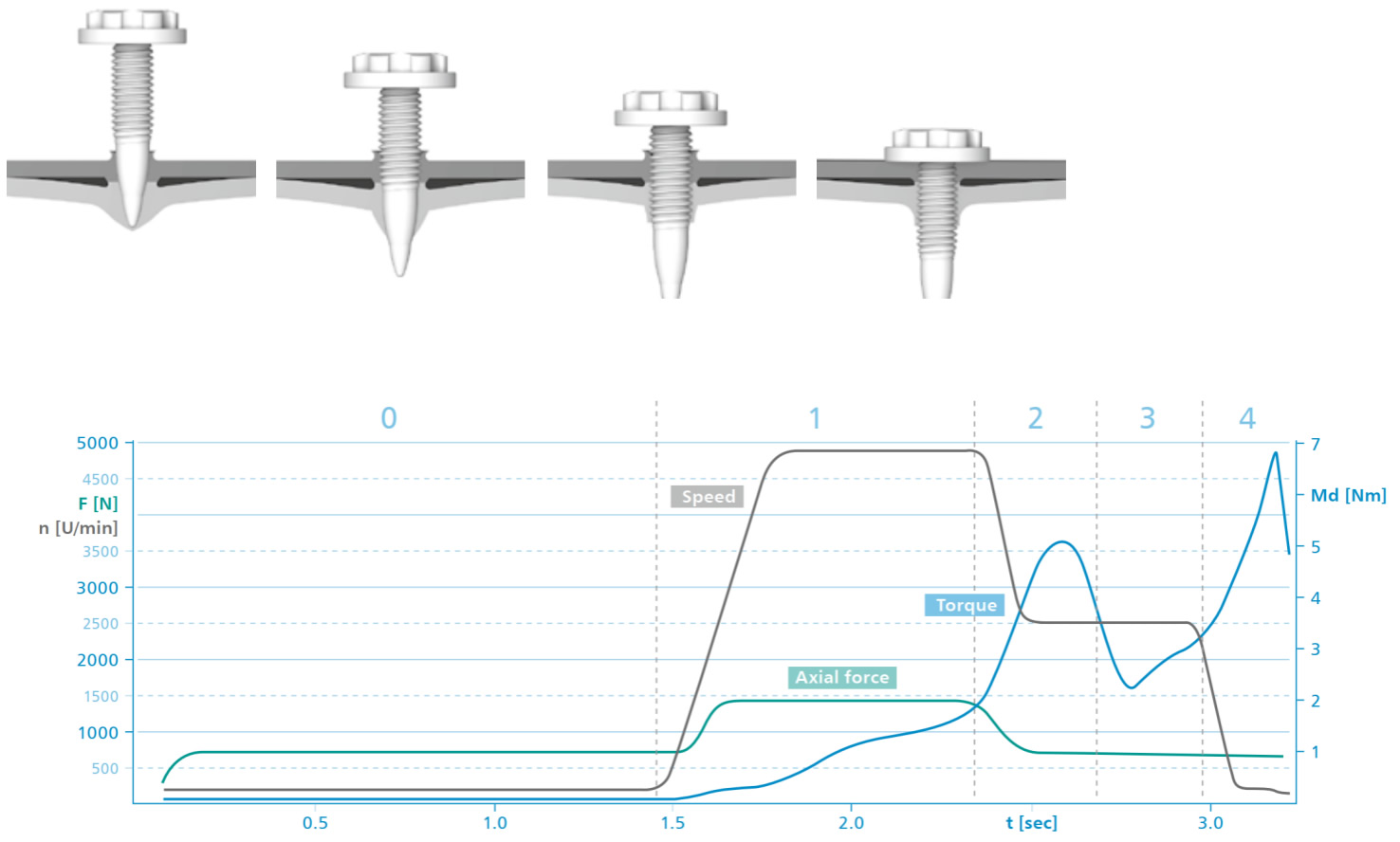

Core Principle:

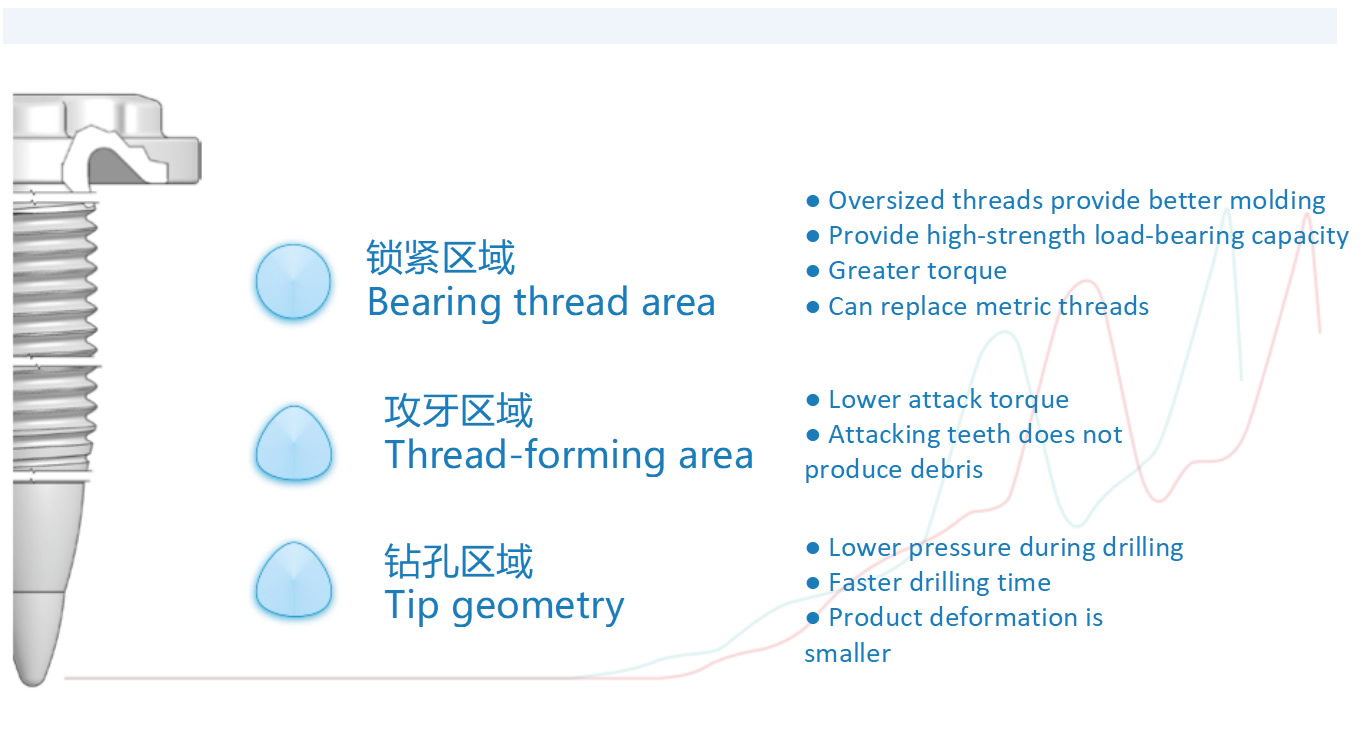

A high-speed rotating screw generates frictional heat to soften the material,penetrates the workpiece,forms threads,and tightens to creat a robust.

• Relies on sophisticated, fully synchronized control of torque, speed, and position.

• Success hinges on perfectly timing the transition between the melting, thread-forming, and final tightening stages.