As a proven alternative to spot welding for steel-aluminum hybrid body structures, SPR technology is becoming an indispensable part of white body manufacturing.

Its superior joint strength, process stability, and cost-effectiveness make it essential for modern applications, including high-strength steel hybrid bodies and integrated die-cast chassis.

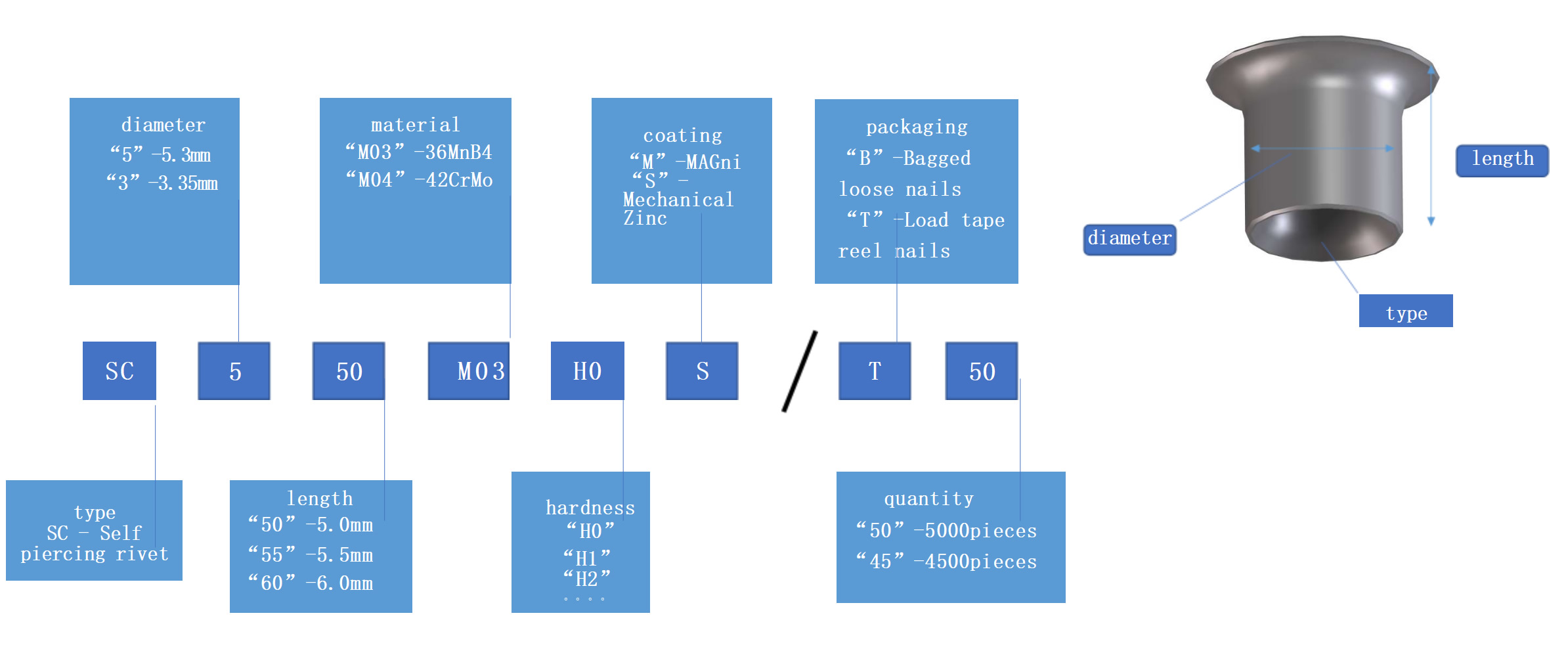

Application: Automotive, General Industry

Material: 36MnB4

Hardness: H0-H6

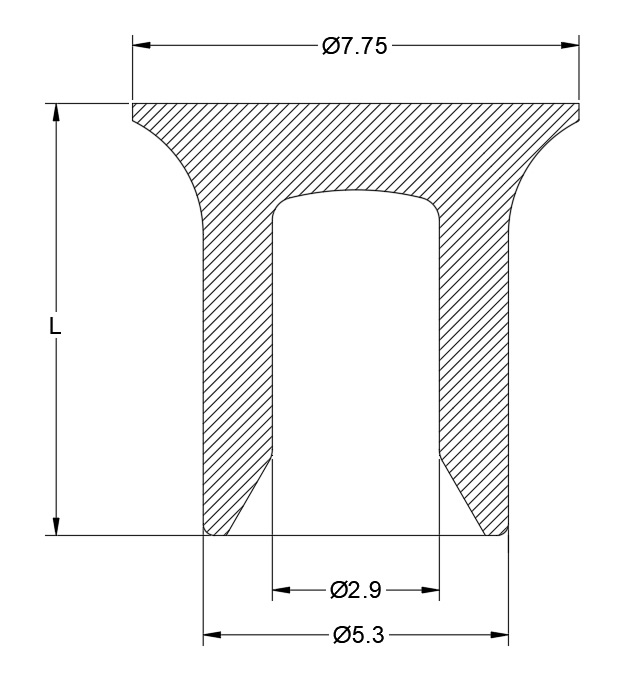

Diameter: 3mm/5mm

Length: 3mm: 3.25mm-7.0mm/5mm: 4.0mm-7.0mm

Coating: Mechanical Zinc, Meijiali, Zinc Nickel Alloy

Suitable for connecting aluminum plates in multiple scenarios, or riveting softer steel plates

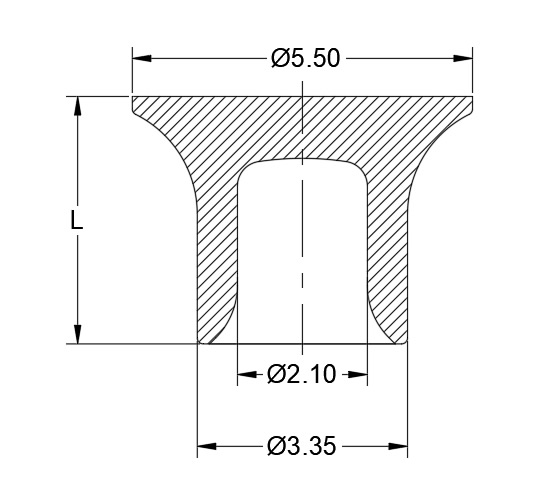

Application: Automotive, General Industry

Material: 36MnB4

Hardness: H0-H6

Diameter: 5mm

Length: 5mm: 7.0mm-14.0mm

Coating: Mechanical Zinc, Meijiali, Zinc Nickel Alloy

Suitable for connecting aluminum plates in multiple scenarios, or riveting softer steel plates

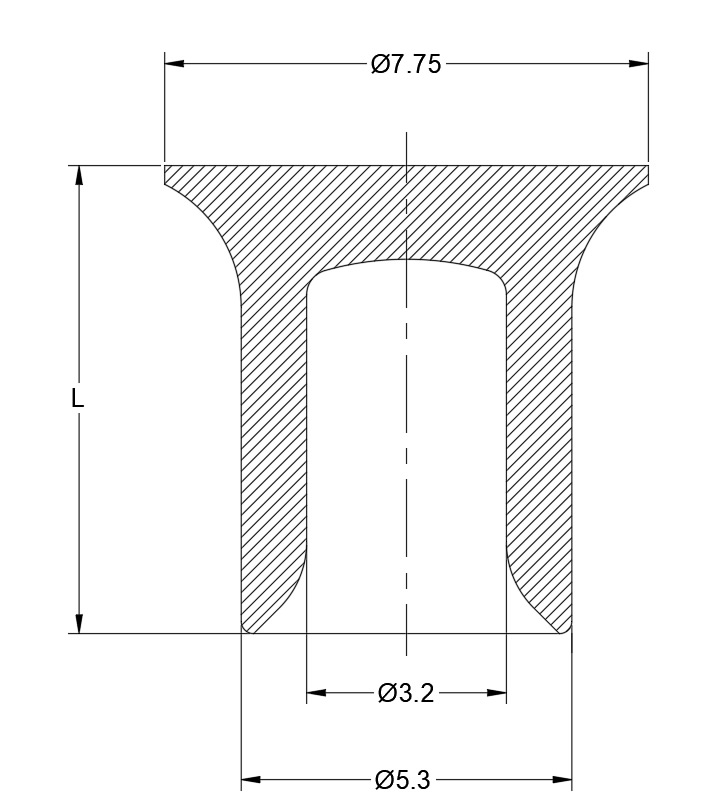

Application: Automotive, General Industry

Material: 36MnB4

Hardness: H2-H6

Diameter: 5mm

Length: 5mm: 5.0mm-11.0mm

Coating: Mechanical Zinc, Meijiali, Zinc Nickel Alloy

High strength rivets, suitable for hot formed steel with an upper layer of 1000-1500Mpa or for situations where there are multiple layers of steel plates on the upper layer

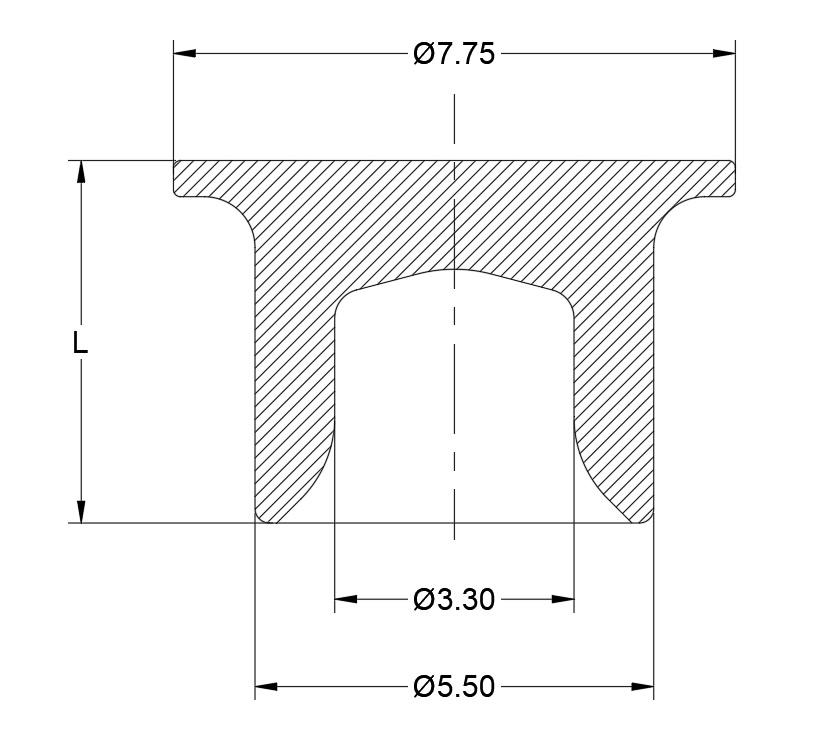

Application: Automotive, General Industry

Material: 36MnB4

Hardness: H2-H6

Diameter: 5mm

Length: 5mm: 5.0mm-11.0mm

Coating: Mechanical Zinc, Meijiali, Zinc Nickel Alloy

Ultra high strength rivets, suitable for hot formed steel with an upper layer of 1000-1600Mpa. The upper layer has multiple layers of steel plates or the lower layer has relatively high strength, especially for thicker applications