FDS, also known as the Flow Drill Screw, is a high-performance fastening solution for modern manufacturing. It utilizes a high-speed rotating screw to generate frictional heat, enabling strong joints from one side without the need for pre-drilled holes.

Core Principle:

A high-speed rotating screw generates frictional heat to soften the material,penetrates the workpiece,forms threads,and tightens to creat a robust.

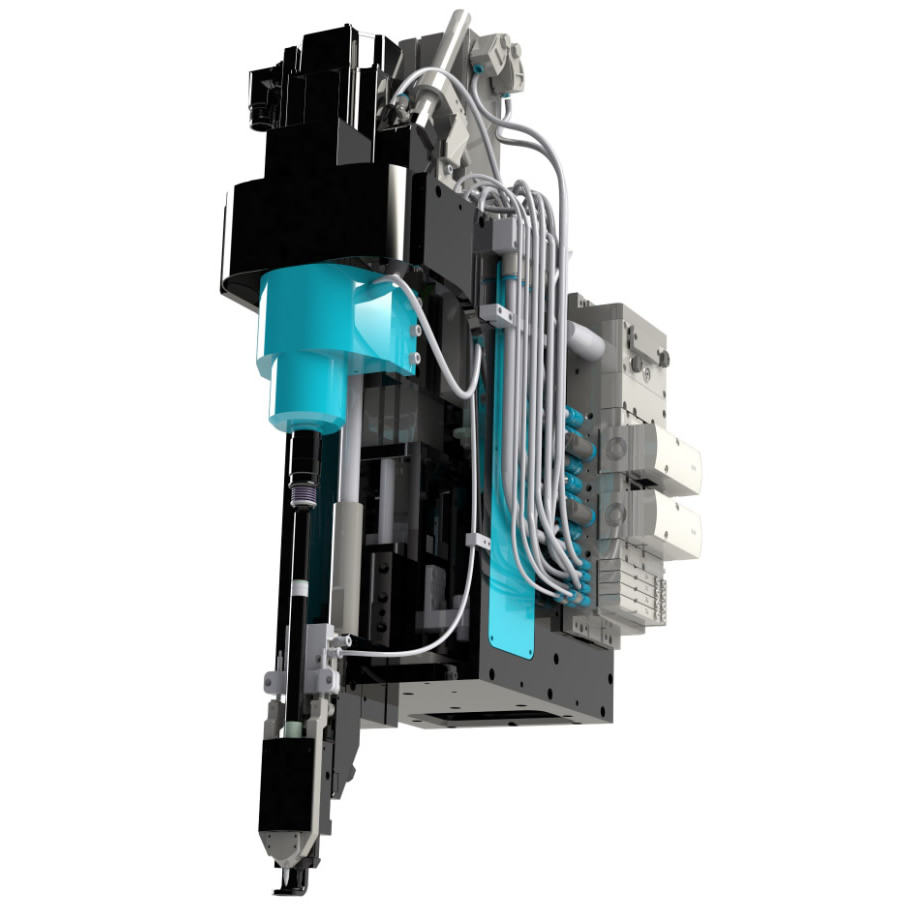

• High-Speed Servo Tightening Axle: Speed up to 8,000 rad/min, torque up to 15 Nm.

• High-Performance Torque Sensor: Real-time monitoring with 1ms feedback precision.

• Independent Spindle & Preload System: Spindle pressure up to 3 kN, preload pressure up to 1.5 kN.

• Active Floating Collet: Adapts to various workpiece conditions, ensuring riveting stability and consistency.

• Multi-Angle Mounting Capability: Suitable for installation at various angles.

• Multi-Gun Sharing & Switching: Supports the use of multiple tools with one controller.

• Expanded Recipe Storage: Capacity to store 500 riveting programs.

• Quality Monitoring & MES Integration: Real-time data tracking with seamless connection to Manufacturing Execution Systems.

• Centralized Group Control: Enables management of multiple systems from a single station.

• Massive Data Storage: 200GB capacity for archiving over 100,000 riveting records.

• High-Capacity Hopper: Stores up to 6,000 rivets to minimize downtime.

• Integrated Rivet Length Detection: Automatically verifies rivet dimensions for quality control.

• Smart Code-Scanning Function: Scans codes to prevent rivet mix-ups, ensuring flawless operation.

• Seamless Multi-Hopper Linking: Offers plug-and-play expandability for uninterrupted production.

• Versatile Rivet Handling: Accommodates multiple rivet specifications without any mechanical adjustments.

● No pre-drilling required

● High joint strength

● Suitable for joining dissimilar materials

● Automation compatible

● Detachable